Fast cloud backups, glitch-free video calls, and responsive gaming share a hidden hero: glass threads carrying light. This guide explains how optical networking works, the parts you’ll handle in the field, and the habits that keep links reliable. By the end, you’ll know core ideas, common components, and a practical roadmap for learning more.

Why light beats electricity for data

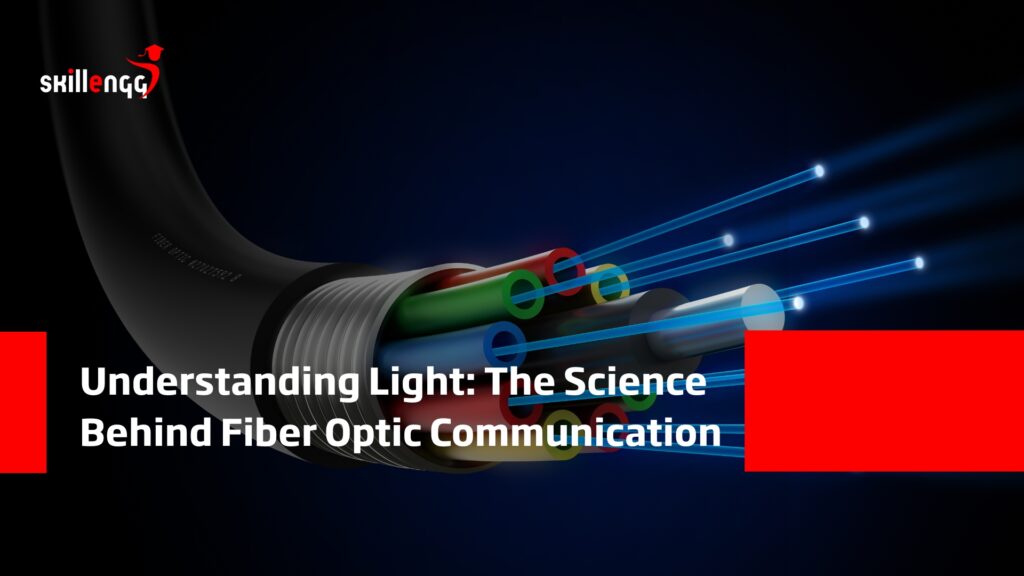

In copper, electrons jostle through metal and lose steam over distance. In glass, photons zip along with tiny losses and zero susceptibility to electromagnetic noise. That’s why modern backbones, data centers, campuses, and an increasing share of home internet rely on optical paths. Lower latency, higher bandwidth, and longer reach come from physics—specifically total internal reflection inside the core, where light bounces forward as if inside a mirror-lined tube.

A fiber optic cable is built to protect that light path. At its heart is an ultrapure glass core, wrapped by cladding with a slightly lower refractive index so the light reflects inward. Protective coatings, strength members, and an outer jacket shield the delicate glass from pulls, moisture, and crush forces. When designed and handled correctly, a single run can carry enormous capacity for kilometers without active repeaters. As fiber optic technology advances, that same plant often handles ever-faster optics with no change to the pathway.

Single-mode vs. multimode: choosing your path

Single-mode uses a very small core so light travels in a single path. The result is minimal dispersion and excellent performance over long distances and very high speeds. Multimode has a larger core that allows multiple paths; it shines at short building-scale links where transceivers can be more economical. If you are building for growth, single-mode often wins for new backbones because the physical plant can remain in place while electronics upgrade over time.

Whichever you choose, treat bend radius as sacred. Exceeding the minimum causes a signal to leak out of the core. Use radius guides, respect conduit fill limits, and plan routes that avoid tight, hidden corners behind racks or ceiling grids. A well-routed fiber optic cable preserves performance and reduces future troubleshooting.

Anatomy and ratings

Cables are rated for the environments they traverse. Plenum-rated jackets are designed for air-handling spaces; riser jackets for vertical shafts; outdoor jackets for sunlight, water, and temperature swings. Some designs add armor for rodent resistance or water-blocking gels for direct burial. Indoors, you’ll see distribution and breakout styles that manage multiple strands neatly inside a single sheath.

The most important daily habit is cleanliness. Dust on an end face scatters light like pebbles dropped into a stream. Always inspect before you connect, and clean with lint-free tools when needed.

Planning the build

Begin with a site survey. Map spaces, measure distances, and document transitions between indoor and outdoor ratings. Identify where patch panels, trays, and slack loops will live. Establish a loss budget that accounts for each connector, splice, and cable segment, and commit to testing against that budget at turnover.

Pulls succeed when they are predictable: respect tension limits, use approved lubricant, and cap ends to keep debris out. Label both ends. After placement, test with a light source and meter, then capture an OTDR baseline.

Installation in practice

The phrase fiber optic installation covers more than running cable. It includes safe handling, clean work surfaces, and careful routing that respects bend limits through every tray, rack, and wall plate. Good practice means staging service loops for maintenance, protecting cables from pinch points, and separating pathways from power. After the physical work, verify performance against the design budget with your meter set and keep those results with the as-built drawings.

Team leads often build checklists for repeatability. A solid fiber optic installation checklist might read: confirm jacket ratings by area, validate pathway capacity, pre-stage cleaning tools, verify pull tensions, inspect all end faces, test and document power levels, and label panels before handoff. When projects get busy, checklists keep quality high.

Joining glass the right way

Two techniques dominate the field. Mechanical joining uses a small fixture and index-matching gel to align ends quickly—handy for temporary or low-count work, with slightly higher loss. Fusion joining uses an electric arc to weld glass after precision alignment; it delivers the lowest loss and best durability.

Professionals rely on precise cleaving for success. A square, clean end face is the single biggest predictor of a strong joint. Protect every joint with heat-shrink sleeves and manage them in trays to avoid micro-bends later. Training and repetition matter here, which is why entry-level technicians practice on scrap strands before touching production links.

That brings us to the phrase many job postings require: fiber optic splicing. Competence with both mechanical methods and fusion machines is a career unlock, letting you repair breaks, extend runs, or build new distribution frames with confidence. Good fiber optic splicing also includes documenting the event loss so the next technician can trust the link.

Connecting equipment and panels

At the edge, you’ll encounter standardized interfaces that click into patch panels and transceivers. Common types include LC for modern high-density gear, SC in older enterprise deployments, and MPO for parallel optics where many strands move traffic at once. Count on the smallest speck of dust to ruin your day, which is why cleaning tools and scopes should live in every toolkit.

When we talk about fiber optic connectors, we’re also talking about hygiene and handling. Always cap unused ports, clean before mating, and avoid touching end faces. Reliable links come from consistent ritual. The same fiber optic connectors will deliver excellent results for years if they are inspected and cleaned every time.

Testing and troubleshooting

Commissioning begins with continuity and polarity checks to ensure the correct strands land on the correct ports. Next comes insertion-loss testing with a stabilized light source and calibrated meter to confirm the link meets the design budget. Finally, an OTDR trace reveals where events occur—connectors, joints, or bends—and measures how much loss each event contributes.

If performance drifts later, start simple. Re-inspect and clean every connection, verify bend radius along the entire run, and compare fresh OTDR traces to your baseline. Most surprises trace back to contamination, kinked slack behind a panel, or mislabeled jumpers. A tidy patch field and a clean fiber optic cable are often the fastest fixes you can make.

Everyday encounters with optical links

From gigabit home internet to hospital imaging, from campus rings to factory lines filled with electrical noise, optical transport shows up everywhere. The virtues are consistent: fast, far, and quiet. As demand grows for cloud apps and media, capacity scales by upgrading transceivers or by lighting multiple wavelengths on the same strand with WDM, while the physical plant remains in place. That enduring headroom is a hallmark of fiber optic technology.

Thinking in decades helps. If you invest in good pathway design, generous radius control, meticulous labeling, and disciplined cleanliness, your link will support faster optics tomorrow without ripping and replacing cable. Treat every jumper and fiber optic cable with the same respect you’d give to live equipment.

Optical Fiber Systems: Job-Ready Technician Course

Ready to go from reading to doing? The Skillengg Optic Fiber Technology course blends fundamentals with focused labs so beginners become confident quickly. Participants practice cleaving, fusion joins, terminations, tray organization, and inspection hygiene; operate light sources, power meters, and OTDRs; and build a proper loss budget from design through verification. Realistic scenarios cover indoor risers and outdoor routes, bend management, and strain relief. Ideal for IT technicians, electricians, and career changers, the program includes mentorship on documentation and job readiness. Graduates leave with portfolio-worthy test reports and a clear path to entry-level roles in telecom and networking.

Conclusion

Optical networking rewards care and craft. Choose the right media, protect bend radius, keep everything spotless, and test against a clear loss budget. With those habits in place, you can deliver links that are fast today and ready for tomorrow’s upgrades. If the ideas here sparked your interest, put them into practice with structured learning and lab time—the surest way to turn curiosity into capability and make an immediate impact on real-world builds. Consistent documentation and labeling shorten repairs and prevent costly mistakes during busy periods.

Fiber optics deliver speed, reliability, and room to grow—if you plan carefully, keep everything clean, and test what you build. Ready to turn know-how into hands-on skill? Enroll in the Optical Fiber Systems: Job-Ready Technician Course at Skillengg.